CNC Bending

& Forming Services

Precision CNC bending and forming services for a wide range of high-quality metal components.

What is CNC bending?

Computer Numerical Control (CNC) bending is a manufacturing process for forming sheet metal (and other materials) into specific shapes and angles.

The CNC press brake has a programmable console into which data is entered. This controls the position of a back stop which, in turn, controls the height and length of each bend. We apply force to a sheet of malleable metal, altering its shape without causing fractures or defects. The process produces a ‘V’ / ‘U’ shape along a straight axis from which we then manufacture all manner of components – from brackets to boxes.

Achieving an accurate bend is the priority for us, irrespective of the tolerances specified. At the same time, we’re measuring the efficiency of the manufacturing process; whether the brief is for a single bespoke enclosure for a valve or 100s of multi-bend brackets, we’re seeking consistency and speed of manufacture.

When do we use CNC bending?

We can bend various types of metals, including steel, aluminium and copper. However, we have to consider factors like material thickness, bend radius and angle to ensure we achieve the perfect fold – preferably using standard tooling to manage the cost for our customers.

One of the key values we offer our customers is guidance. For example, we’ll question a brief that specifies welding if we think bending is the better option.

Call For a Quote:

01438 355687

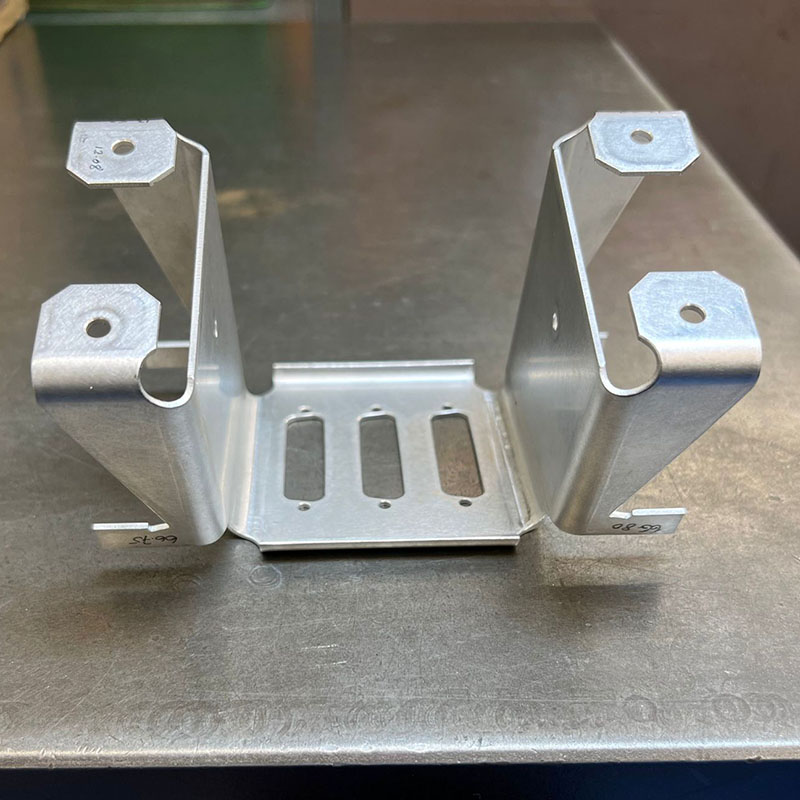

Components created using our CNC bending and forming services

Here’s a snapshot of the kind of components we manufacture for customers from a broad range of sectors including aerospace, telecoms, AV and pharmaceutical:

Brackets for various purposes

Brackets are essential components used to secure and support various pieces of equipment and structures. With CNC bending, we can produce brackets in a wide range of sizes and configurations to meet your specific requirements. High tolerance brackets with awkward bends going in different directions and requiring individual tooling? No problem – bend, de-bur, tap, clean up, pack and out the door. Whether you need simple L-shaped or complex multi-bend brackets, our CNC bending capabilities ensure precise and reliable results.

Enclosures for gas tank valves

Enclosures play a crucial role in protecting electronic components and machinery from environmental and physical damage. Our pharmaceutical customer asked us to design and manufacture protective housing to attach heavy gas tank valves to a brick wall. We came up with heavy gauge stainless brackets and covers. Using CNC bending, we fabricated bespoke enclosures featuring intricate shapes to precise dimensions that accommodated the equipment perfectly. We also manufactured and installed galvanised fencing round the Co2 tanks.

Precision aluminium metal cleats

With CNC bending, we produce cleats in various shapes and sizes, with a corrosion-resistant protective coating where necessary. We produce precise bends and angles and often working with tolerances as tight as 0.05mm.

Heat shields for aerospace

Heat shields are essential components used to protect sensitive equipment and components from high temperatures and thermal radiation. With CNC bending, we fabricate heat shields with intricate shapes and configurations to provide effective thermal insulation and protection, such as for aerospace applications.

Why use Alroys CNC bending services?

We’re thoughtful, resourceful metal-workers so your project is in safe hands. Here’s a breakdown of the benefits of our CNC bending and forming services:

Advanced equipment: We use state-of-the-art CNC bending machines equipped with the latest technology to ensure precise and consistent results.

Our experienced team: Our team of skilled engineers have years of experience in CNC bending and forming. We know how to get the very best out of the technology so we offer all our customers high quality craftsmanship and great attention to detail.

Custom solutions: We work closely with our customers to understand their unique requirements and provide custom solutions tailored to their specific needs. We design components from scratch, as well as adapt and improve existing designs.

Cost effective solutions: Alroys is well known for coming up with cost effective solutions such as reducing the number of bends in a component design or finding a way to use standard instead of bespoke tooling.

Fast turnaround: With our efficient production processes and streamlined workflows, we offer fast turnaround times to meet tight deadlines and project timelines. Our focus is the most cost effective route to production, especially where repeatability is involved.

Finishing options: Alroys provide various finishing options like powder coating, zinc plating or anodising. As architectural metal workers, we’re well-used to the importance of enhanced aesthetics as well as corrosion resistance that finishing brings to a component.

Contact Alroys for fast, accurate and customised CNC bending services.

Call For a Quote: 01438 355687

Alroys Sheet Metal Services

Prototyping

Take control of the unknown by testing first with a prototype. We give you the ability to fully test a design concept, iron out unwanted flaws at the earliest stage and create a working model, approved by your project team.

CNC Punching

By utilising the combination of 3D modelling, CAD/CAM software and Trumpf technology, Alroys is able to offer a complete solution to all your requirements, no matter how unique.

CNC Bending (or Forming)

With advances in technology, CNC (computer numerically controlled) bending technology now gives you the ability to produce almost any component design, saving time and money along the way.

Sheet Metal Welding

This manufacturing process fuses metals together using extremely high temperatures. During cooling, the joints harden, creating permanent structures.

Sheet Metal Assembly

Prior to installation, the assembly stage is the realisation of your project. We take each component part and, in our manufacturing facility, we assemble them, testing each for fit and quality.

Contact Us

Free Consultation

Talk to us about your next project

With over 60 years experience, we have built up a reputation of providing high quality products, on time delivery and professionalism.

As a leading steel manufacturer in the UK, we can handle any project using materials such as stainless steel or aluminium. Whether you come to us with a blank canvas or ideas already in mind, we will take on any request and contend to calculate and guarantee exceptional results.

Call us to discuss your next project.

+44 01438 355687

Arrange an appointment

If you'd like to visit us to discuss your next project in person, please use the number above to arrange a time suitable for you.

Download our brochure

Click here to download our brochure.

Depending on your browser settings, the brochure will either open in a new browser window (save to your computer to view) or will download directly to your computer. You will require a pdf reader to view our brochure once saved to your computer.