Who We Work With

at Alroys

In every case we guide and recommend in order to get their desired end result, working from the design stage, through planning, manufacture and assembly / installation. Our customers’ goals become our goals. So our input at the design stage (even on a repeat pre-determined precision part) will always impact positively on cost effectiveness.

Sometimes, we’ll be working on something completely new for both parties. Our principles remain the same, however: spend time on understanding exactly what’s involved and take the customer with us on the journey to their successful finished piece.

What do our customers do?

- Procurement and purchasing

- Component engineering

- Structural engineering

- Project management

- Construction consultancy

- Architecture and interior design

- Facilities management

Call For a Quote:

01234567890

Procurement and purchasing

Procurement and purchasing managers oversee the sourcing of an organisation’s products and services. They often specialise in a product or service especially if they’ve worked in that specific area in the past. Naturally, they are cost-conscious and focused on buying from reputable suppliers. Our philosophy is to make it easy for our procurement customers to choose us. So, we make sure they are familiar with the quality of our work, our attention to regulations and standards , and our effective communication skills. As a consequence, we are on the approved suppliers list of many large organisations.

Component engineering

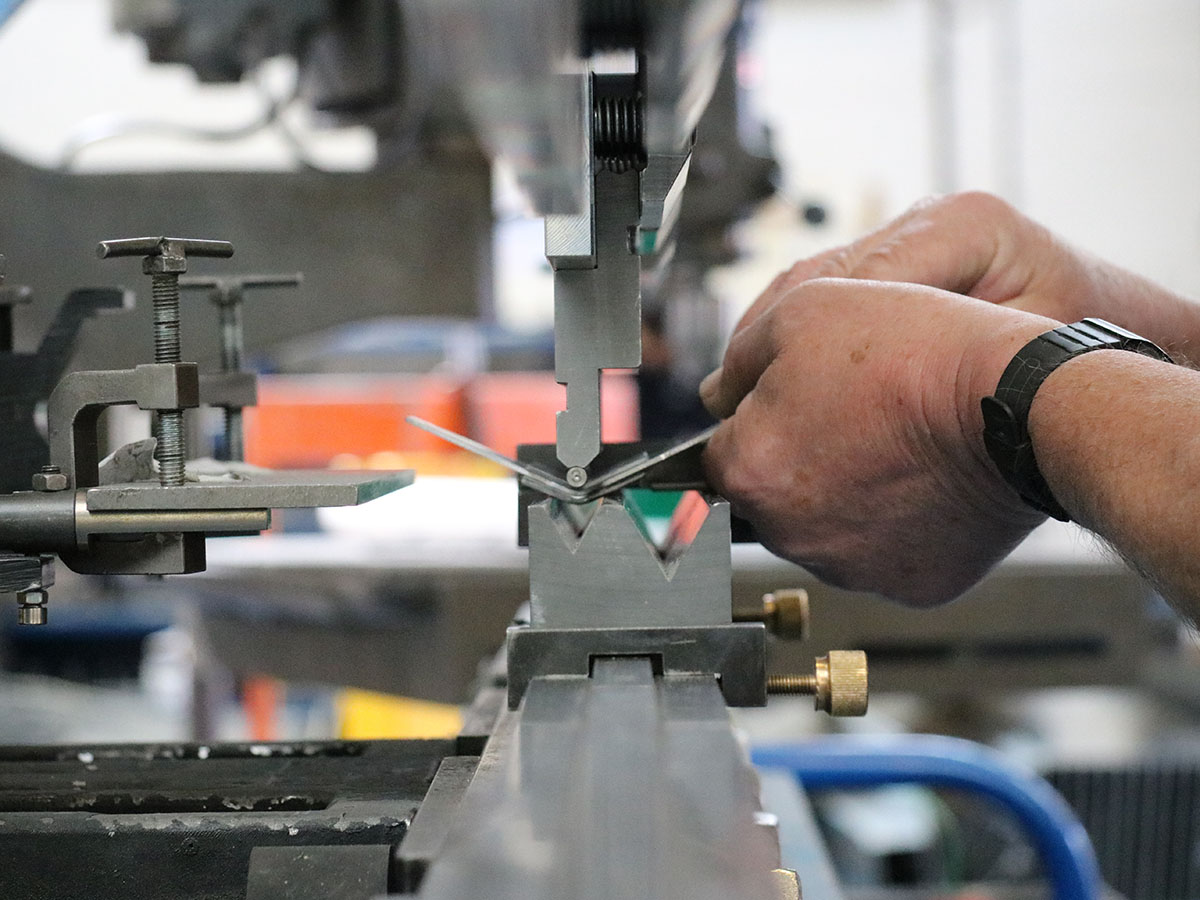

Component engineers manage the design spec for individual parts as well as making sure those parts work together where necessary. With our telecoms customer, we’ll design a bracket according to their brief, then create a number of prototypes so we can collectively narrow it down to a couple of options for further consideration. With our aerospace customers, we simply recreate a component – eg a heat shield – according to their very tight tolerances.

Structural engineering

Structural engineers are responsible for the viability and safety of structures. We work with them as part of a team alongside architects and interior designers. At the start of a project we’ll be involved in providing cost effective solutions, and this will include the installation stage. For example, working on residential properties in London can throw up a number of access challenges. As with all our jobs, we approach each challenge like a puzzle to be solved. So, if we have to splice an RSJ into 3 parts and wheel it on a trolley, through a gated community to get it onto site, that’s what we’ll do.

Project management

Project management can be a huge juggling role – overseeing the planning and delivery of construction projects, ensuring that work is completed on time and within budget. The project managers we work with are busy people with a broad range of technical knowledge. Often they are working on multiple projects organising logistics, delegating work and keeping track of spending. Consequently we see it as our job to be a safe and resourceful pair of hands. Naturally this calls for our own high standard of project management.

Project managing other trades and specialist suppliers

- Glass and wood for balconies and balustrades: we might be hired simply to do the metal fabrication for a balcony or stairwell. But if it makes sense for us to source other elements, such as the glass balustrade or a wooden handrail, we’re more than happy to relieve our customer of the task.

- Readiness for utilities, media and IT stages: when a job involves making a building or structure ready for the next specialist stage we make sure we know what’s involved. For example creating the framework to support air con units. Our aim is to make it as easy as possible for the contractor to complete their part of the job.

We work closely with other trusted suppliers – be it glass, wood or specialist finishers – people we’ve forged good relationships with as well as suppliers approved by our customers. Ultimately, it means we’re not just doing our job well, we’re also facilitating other contractors to deliver high quality.

Call For a Quote:

01234567890

Construction consultancy

Many of our construction customers are consultants managing the design and delivery of complete construction projects, such as new builds and refurbs. Inevitably these jobs are complex and time-pressured for our customers. As metal fabricators, we might be hired to carry out a seemingly straightforward fabrication job, such as security grids in an underground car park or protective canopies over an entrance. We know what our customer wants for their end client, but we may need to rethink certain elements regarding the manufacturing process or the installation stage. We might even recommend different materials and fittings. The time and attention spent early on at this design and planning stage will reap huge benefits in the long run – both in terms of budget and schedule.

Working round other trades and suppliers

Call For a Quote:

01234567890

Architecture and interior design

We work directly with designers and architects so we understand the importance of remaining faithful to the vision. Often it means the focus is very much on ‘how are we going to achieve this’: sourcing a specialist drill to ensure we can install some beautiful internal panelling without showing the fixings. Or working out the best way of achieving uniformity with 24 elegant perforated doors in an uneven environment. From material selection to manufacturing process and installation, we’re more than ready for the unexpected.

Facilities management

Facilities managers are a vital support service, contributing to the effective, efficient and safe running of a site so an organisation can deliver its strategic and operational goals. Often the projects require some clever thinking, the kind of job our customers describe as “too challenging for anyone other than Alroys”.

How do we work with them?

- Follow their brief – to the letter if the design is tried and tested, and precision has been predetermined. In every case, have the end goal in mind.

- Take a schematic idea and turn it into a viable structure or part – eg reducing the need for specialist tooling or cutting down the time during the manufacturing stage.

- Question and plan for everything – tolerances, material choice, optimum production processes, fixing requirements, on-site access, etc.

- Comply with standards and regulations: including H&S, ISO 9001:2015 and EN1090-02.

Call For a Quote:

01234567890

Hard-working metal components and fabricated structures for every customer

Alroys has a great approach to service: we’re reliable, skilled, experienced and resourceful. We’ll work with you to get your project up and running successfully without delay – whether it’s a small, high tolerance component or a large fabricated metal structure. We’re based in Stevenage but we find our customers all over the country.

Whether it’s introducing you to a different process or recommending you use an alternative material, we’ll get the maths right so your metal component or fabricated structure does the job you want it to do. Get in touch, and let’s work together on your metal component or metal fabrication project.

Contact Us

Free Consultation

Talk to us about your next project

As a leading steel manufacturer in the UK, we can handle any project using materials such as stainless steel or aluminium. Whether you come to us with a blank canvas or ideas already in mind, we will take on any request and contend to calculate and guarantee exceptional results.

Call us to discuss your next project.

Arrange an appointment

Download our brochure

Depending on your browser settings, the brochure will either open in a new browser window (save to your computer to view) or will download directly to your computer. You will require a pdf reader to view our brochure once saved to your computer.