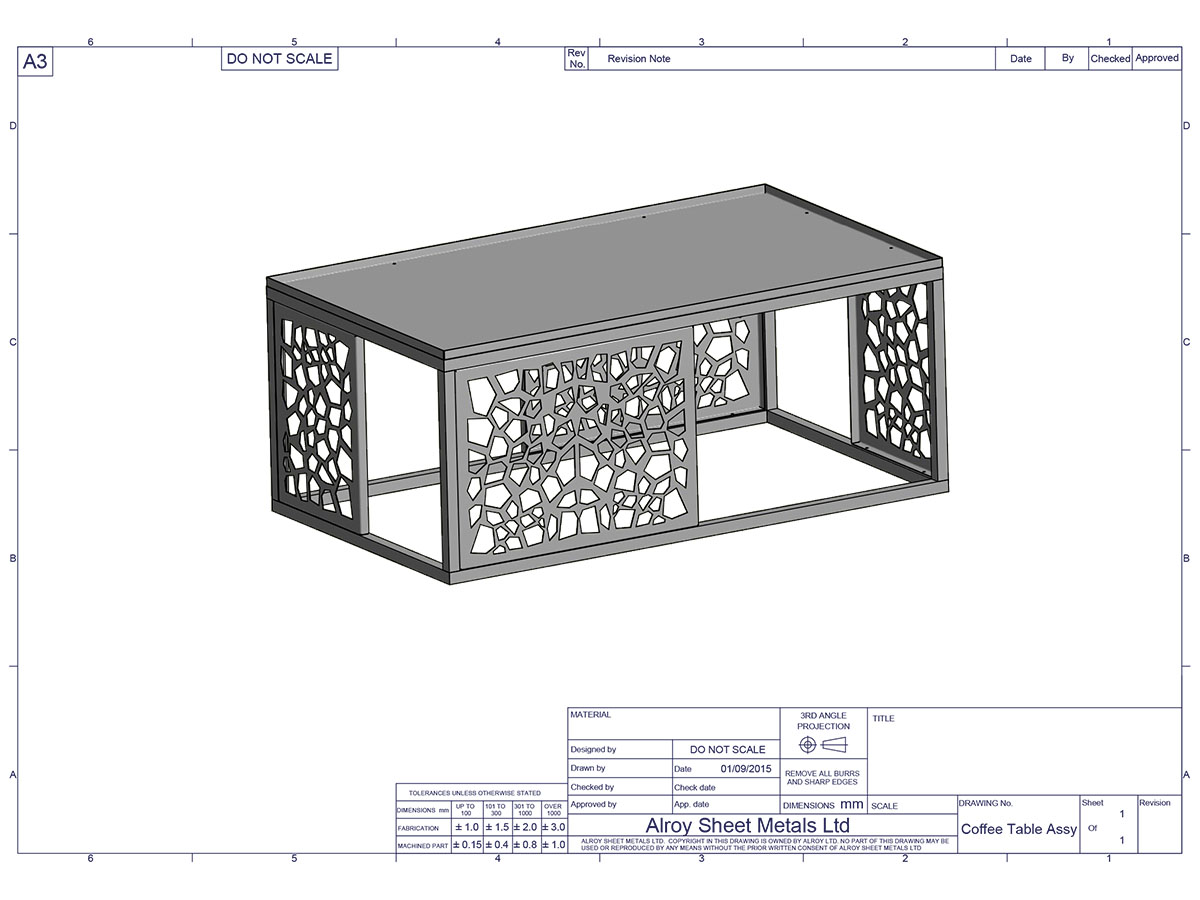

Sheet Metal Services

We’re renowned in the UK for our sheet metal work, both precision and large-scale, delivering metal work to the highest standards.

Sheet Metal Services

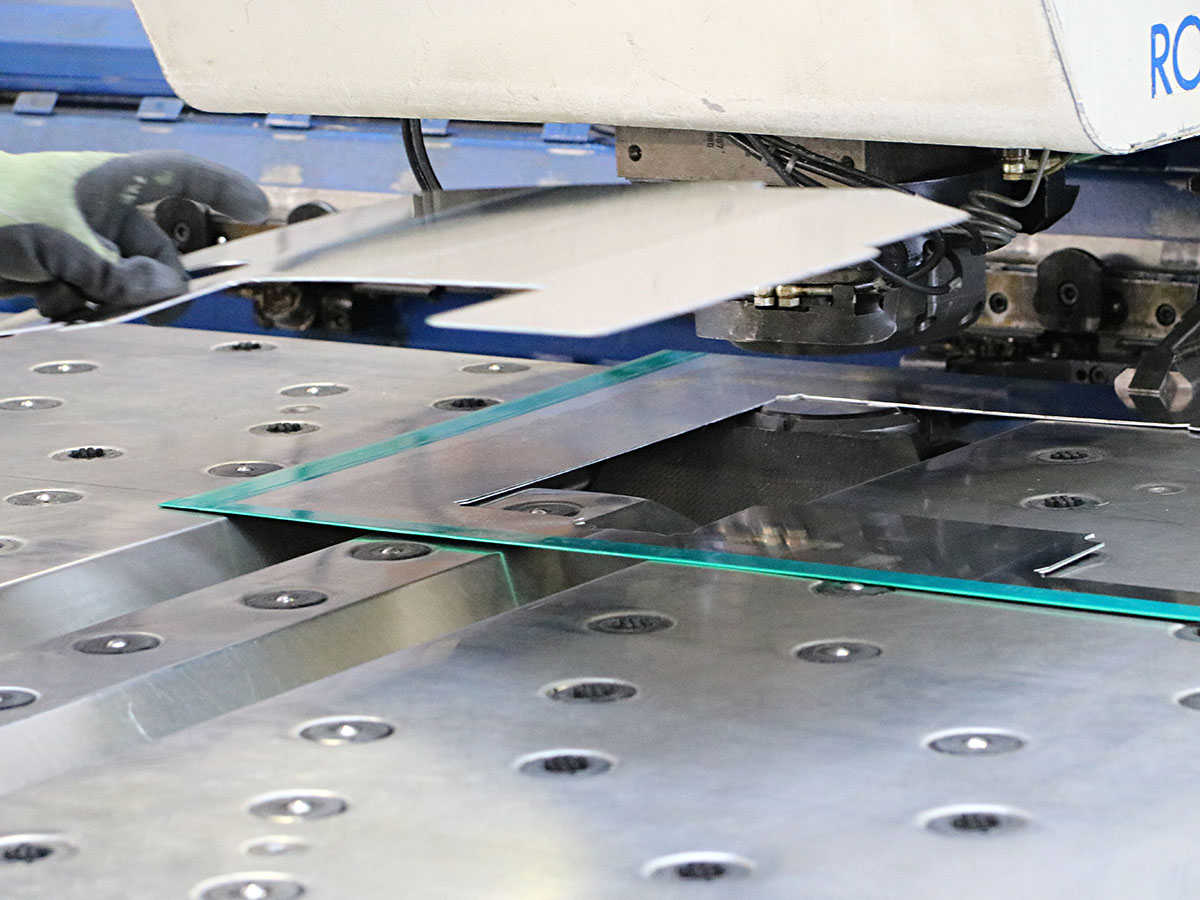

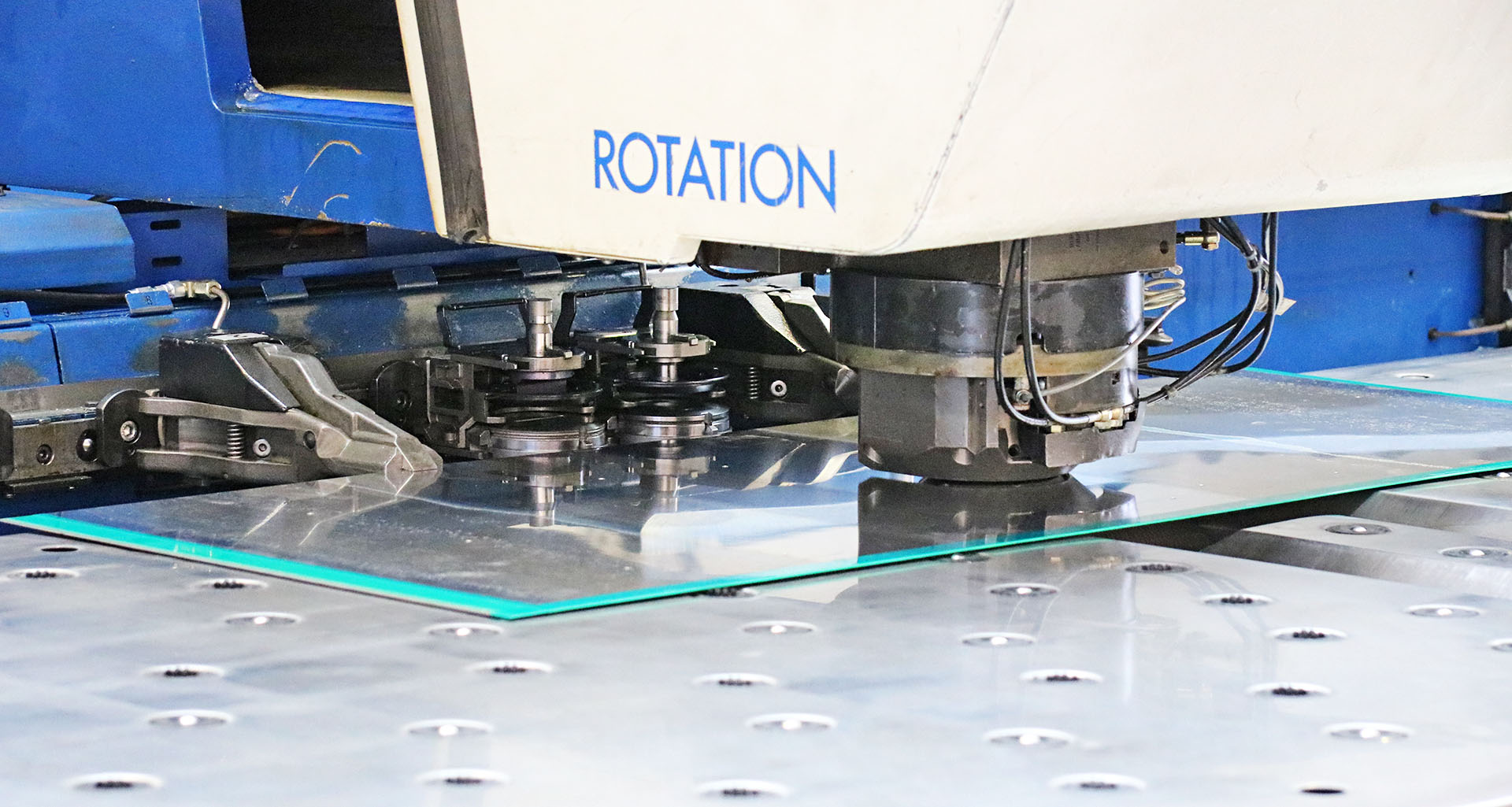

For over half a century, sheet metal has been at the heart of our business. From the beginning, we’ve been committed to creating high-quality products for our customers and this commitment continues to this day.

In this section, we’ll look in detail at our sheet metal services. If you’ve got a project in mind, get in touch today and we’ll be happy to show you how we can help you bring it to fruition.

Contact Us

Free Consultation

Talk to us about your next project

With over 60 years experience, we have built up a reputation of providing high quality products, on time delivery and professionalism.

As a leading steel manufacturer in the UK, we can handle any project using materials such as stainless steel or aluminium. Whether you come to us with a blank canvas or ideas already in mind, we will take on any request and contend to calculate and guarantee exceptional results.

Call us to discuss your next project.

Arrange an appointment

If you’d like to visit us to discuss your next project in person, please use the number above to arrange a time suitable for you.

Download our brochure

Click here to download our brochure.

Depending on your browser settings, the brochure will either open in a new browser window (save to your computer to view) or will download directly to your computer. You will require a pdf reader to view our brochure once saved to your computer.