Precision Sheet Metal Fabrication is for the specialist

Precision sheet metal fabrication

There are a number of industries for which precision sheet metal fabrication is really important in the manufacture of components. Aerospace, defence, medical devices and telecommunications – they all have need of metal components manufactured to very precise levels of accuracy. The use of ‘exotic’ materials (copper, brass, aluminium, steel, and other alloys) is equally important. They are particularly suited to the variously demanding environments in which these industries operate.

The components we supply to clients in these industries include cleats, shields, and electrical connector brackets, panels and boxes. Some are new products but many are repeat or involve minor adjustments. Depending on the material and the type of part we’re manufacturing, we’ll use a range of techniques, such as CNC punching and forming, welding and assembly.

Here’s an idea of what’s involved in manufacturing components for precision industries.

Precise project management

Professional project management starts with an assessment of the design. With our clients in aerospace, this is often just a matter of familiarising ourselves with their needs because the design will have already gone through a number of approval stages.

Ensuring the availability of materials means effective procurement is critical to the success of a project. For example, if there’s a 12 week lead time for a specific type of rivet, the sooner we know the sooner we can factor it into our calculations.

Where sub-contracting is necessary e.g. machining or finishing – we often select from our clients’ approved list. We’re seeking high quality, precision and reliability. Therefore, although we’ll be supervising their progress and final output, the better their processes, the less opportunity for hitches and delays to the project.

Understanding ‘precision’ industries

From tolerances to using the right kind of material, accuracy and attention to detail is fundamental to precision sheet metal fabrication.

Tolerances

Tolerances are typically very tight in ‘precision’ industries. This allows for relatively minimal variation in size, position, or other physical properties. This is massively important in aerospace because, usually we’re manufacturing just one component of a larger structure, so the build up of tolerances has to be managed. As one of our customers, who manufactures satellites, said: “We only get one chance to get this into space!”

Exotic materials

Materials with high alloy content are known as ‘exotic’ or ‘super’ alloys. They offer enhanced performance such as strength and durability. They’re resistance to oxidation and corrosion, and less likely to deform at high temperatures or under extreme pressure. Consequently, they make the best materials for demanding working conditions, such as withstanding harsh weather and heavy impact.

Two examples are:

- Stainless steel (316): ideal for medical devices as it’s corrosion-resistant, thus able to deal with the high temperatures and harsh chemicals used in the sterilisation process. The finish can be polished smooth, again perfect for sterilisation purposes.

- Aluminium (AMS QQA 250/4): offers high-yield strength with good fatigue resistance and excellent toughness. This alloy is resistant to corrosive attack if cladded, and stands up to stress corrosion cracking in the T851 temper, which is ideal for aerospace use.

The manufacturing process

There are a number of manufacturing stages, all of which are geared towards precision sheet metal fabrication:

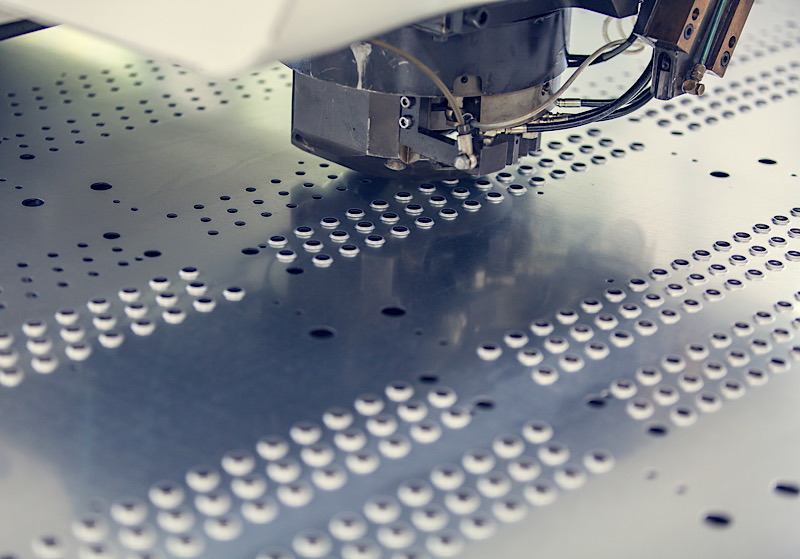

CNC Punching

Appropriate for steel, aluminium, copper, brass, and other alloys. This is one of the most exacting techniques allowing tolerances of +/-.020mm. Using various shaped tools, apertures such as holes, obrounds, squares and slits can be quickly and accurately produced. Within the aerospace industry, CNC punching is a preferred method for cutting aluminium as heat isn’t produced so the material properties are not affected.

CNC Lasering

An alternative to CNC punching using the same materials and to the same accuracy. CNC lasering has the advantage of being able to cut through thicker materials and create contours with greater speed. Apertures can be slower to create than a single hit (CNC) punch. The heat produced will change the material properties which means CNC lasering isn’t always suitable for aerospace work.

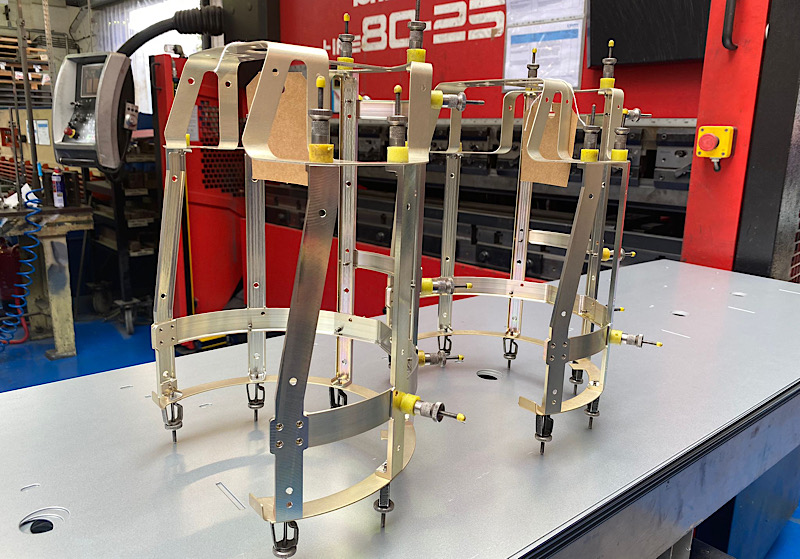

CNC Forming

The programable console, back stops and fingers enable several bends to be created during one handling of the component, offering speed and accuracy simultaneously. It’s worth highlighting that, often when working with exotic alloys, the temper of the material is harder which can lead to cracking. This can be easily rectified by increasing the bend radius and top tool. Alternatively, parts can be manufactured in a lower temper, then heat-treated after forming to the temper specified on the drawing. Clearly, it’s important to anticipate the likely increase in cost and time involved in such a process before the parts are produced.

Welding

Used to produce a clean, strong, and precise join between two metal parts. Depending on the size and type of metal used, we choose between Gas Tungsten Arc (TIG), Gas Metal Arc (MIG), or Shielded Metal Arc (Stick) welding.

Finishing

There are various processes and treatments available, each offering different protections and appearances depending on the component and customer requirements. Some treatments are purely cosmetic whilst others, such as alocrom and anodising, also protect alloys from oxidising. Our aerospace customers require NDT which is non-destructive testing of their components. This detects the presence of hairline cracks which could cause a severe failure of parts during flight.

Painting

Painting can also provide more than a pleasing finish, with protective properties existing in both the pre-treatment and top coat processes. For example IRR (Infra-Red Reflective) paints are used to keep components cooler. Solar heat can pass through the topcoat pigments to the primer coat, reflecting the heat away, which makes it the perfect choice for structures such as aircraft.

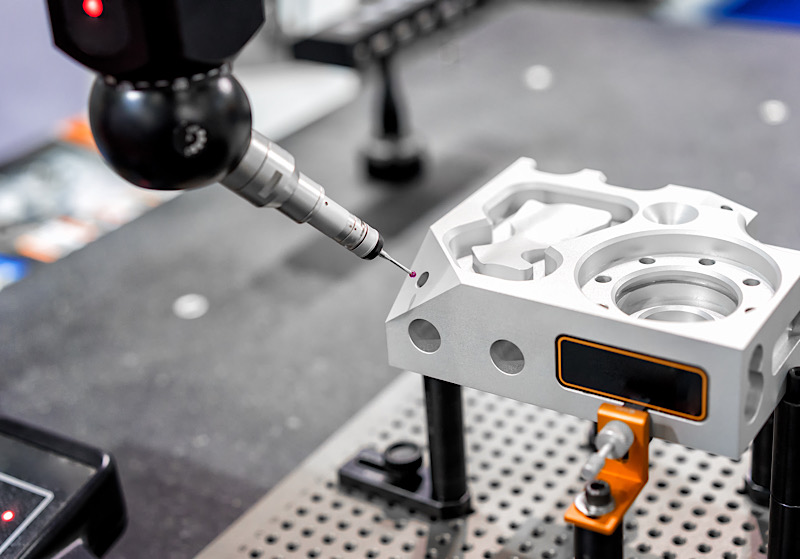

Inspection and quality control

As you would expect, inspection and quality control is a vital part of precision sheet metal fabrication. First Article Inspection (FAI) is used to assess whether the quality of the manufactured components meet the customer’s specification. The parts undergo ‘dimensional inspection’ and are cross-referenced with the drawing. The level of inspection can involve every single part, or a random selection from the total batch produced.

The inspection includes thoroughly checking every process – such as material specification and finishing. This ensures compliance and full batch traceability.

FAIs are incredibly thorough and particularly useful if the product is being produced for the first time (or production has paused), or a product’s design has changed.

Sheet metal fabrication is for specialists

Precision sheet metal fabrication is an area of work for the specialist: accurate manufacturing to a precise set of drawings with professional project management to ensure adherence to both time and budget. Alroys is well suited to this kind of work in terms of our skill, experience and enthusiasm.

How can we hep you with your next project?

Contact us today and get started.