Getting sheet metal design right

Getting sheet metal design right at the beginning of a project, massively improves the chances of a successful outcome. Better performance plus economies in terms of cost, timescale and waste, are all boxes that good design will tick.

To Alroys, good sheet metal design involves 3 important principles:

- The design must deliver what the customer wants: what’s the intended use, how should it perform, what should it look like, where will it be installed?

- Then, design for manufacture (DFM) might impose some restrictions on your design in terms of what’s possible, repeatable, most economical and time efficient

- Finally, factor in a prototype, or test stage, to confirm that you’ve ticked the above 2 boxes.

Let’s take a brief look at each stage of sheet metal design, and see how they fit together.

Design must deliver what the customer wants

The whole point of a design is to achieve the right result for the customer. We approach every project in the same strategic way: carrying out a full technical review of the customer’s design or concept, and the environment in which it is being used or installed. Designs come across to us in 1 of 3 ways:

1. Design by CAD

Regularly criticised for not being in the ‘real world’, CAD designs rarely take into account material behaviour, the limitations of standard tooling, minimum distance or bend radius. Anything is possible in CAD but not in the real world of budget and time constraints.

2. Previously-used design

Repurposing and adapting a design works in principle but not if it’s based on the we’ve-always-done-it-this-way school of thought. Apart from inheriting a questionable spec, if the purpose of the design is different, it’s unlikely to be appropriate, or even safe for another project.

3. Idea on a back of an envelope

Arguably the least dangerous option because a hand-drawn idea or a photo of something implies the customer is still at concept stage. This means the design can be developed in a more logical way according to DFM principles.

In every case, we seek to understand what the customer is trying to achieve. This means getting a ‘wider view’ of the job – beyond the drawing of a component. Knowing the weight that a bracket is expected to withhold, for example, is pretty key to ensuring it’s fit for purpose.

As sheet metal professionals we do the important strategic thinking for our customers.

Design for manufacture

DFM is a recognised industry practice. It’s also a self-explanatory no-brainer that’s frequently ignored. It requires that 2 criteria are satisfied:

1. Is it manufacturable and repeatable?

Sometimes this literally means is it physically possible to make something?

2. Is it the most economical way of manufacturing?

And is it possible to do so multiple times, with relative ease?

Run time and material management are prime examples of where both time and cost can be reduced. So, we’ll query drawings that specify holes in different sizes because of the time involved in setting up the necessary tools. We’ll also explore whether it’s feasible to replace welding with bending in order to reduce run time which could vary from a couple of minutes to hours depending upon the type of job.

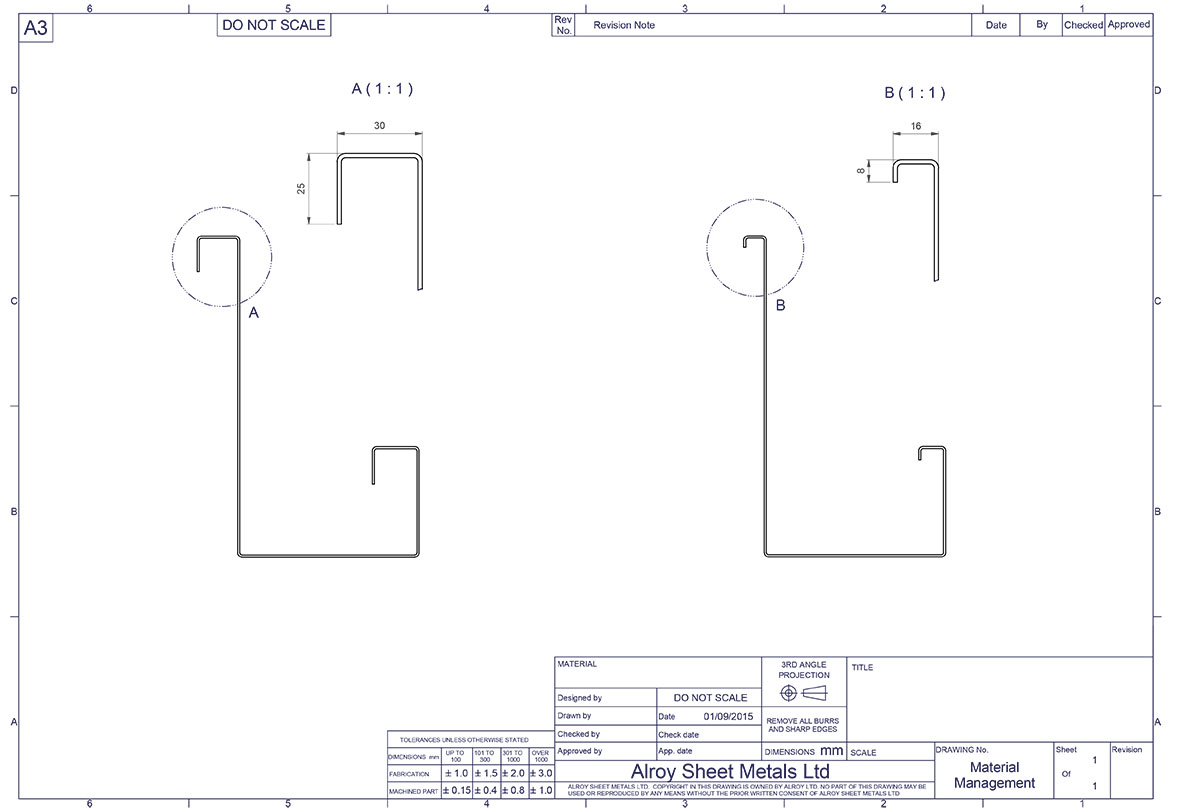

Good material management leads to less wastage so if we can get more components out of a sheet of metal, we’ll make the calculations then recommend an appropriate design change to our customer. The example shows that by reducing the flange sizes, but still keeping their strength, we were able to save a total of 62mm worth of material (31mm x 2) and produce an additional part from the same size sheet of material.

Prototype or test to be absolutely sure

Nothing beats testing something out; producing a prototype so you can see how it works, how easy (or difficult) it is to manufacture, how long it takes. Testing how the chosen material behaves, such as aluminium, may cause you to reconsider the bend radius, for example. Cheaper materials should prompt the question “Are they up to standard?”.

We recently undertook some R&D with a construction customer who wanted to experiment with a thinner material for the steel framework. The aim was to reduce cost but we were concerned about stability – would the steel framework withstand concrete being poured up against it, or would it bow and distort? Going ahead with mass production, without testing if the thinner gauge steel was up to the job, could have set the whole project back. Instead, we recreated the whole scenario to see how it held up.

Even if you’ve interrogated the design intent, and satisfied the DFM criteria, carrying out a test or creating a prototype will confirm for sure that it’ll work. If your production run is as many as 1,000, producing 1 or 2 for final testing is the logical thing to do.

Sheet metal design implies best practice

There are some often-quoted stats claiming that manufacturers spend 30% to 50% of their time fixing errors and almost 24% of those errors are related to manufacturability. Sheet metal design is such an important part of getting it right first time because it should satisfy 2 key issues:

- Will the design achieve the required end result?

- Is it manufacturable and repeatable, both physically and economically?

Sound sheet metal design is not losing sight of what the customer wants. Then, if you apply the principles of DFM and carry out a test piece, production will be as successful, fast and economical as it’s possible to be.

Want to discuss your next project?

Contact us today and get started.