Yield Strength Vs Tensile Strength: which is better and why?

The yield point is the maximum stress a material can endure beyond which it begins to permanently deform and is unable to return to its original dimensions. Whereas, tensile strength is the maximum stress on a material before it fails and, literally, breaks.

In many instances, yield and tensile both feature in stress strain tests.

What is yield strength?

Yield strength is the maximum stress that can be applied to a material, such as steel, before it changes shape permanently and will not bounce back. This is testing the ‘ductile’ nature of the material. If the stress level does not reach the yield point, the material will return to its original shape once the stress is removed.

Put a certain amount of stress on a plastic ruler by bending it and it will bounce back to a flat shape. At some point, however, the amount of stress will force the ruler to yield and either snap or stay bent out of shape. You’ll come across the term ‘proof stress’ which is the point at which a particular degree of permanent deformation occurs in a test sample. For example, 0.2 percent extension.

Yield is a vital test for a structure where an element of ‘give’ is required – such as a suspension bridge flexing with the weight of vehicles and movement from the wind. Any permanent deformation is termed as failure.

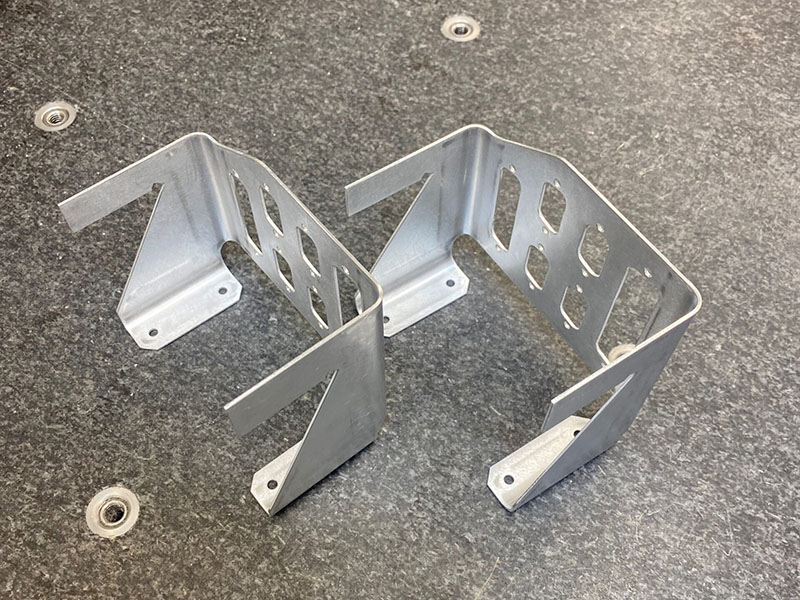

However, the idea of ‘failure’ is not always a negative: reaching deformation at a 90 degree bend is necessary in order to create a bracket, for example. Then tensile strength becomes the important factor.

What is tensile strength?

Tensile strength is measured by the maximum stress (or ‘elongation’) that the material can withstand while being stretched or pulled before actually breaking. It demonstrates how ductile, or malleable, the material is and therefore able to be shaped and moulded. Materials with high strength against tension stress are useful for aerospace applications due to the speed and pressure differences experienced by aircraft structures.

The following three terms will help you understand more about yield and tensile tests, and how they work together:

Yield Strength

Yield strength can be seen as the first stage of tensile testing. Having applied maximum stress to a metal before it begins to yield and change shape permanently, the tensile test for brittleness can then be measured.

Ultimate Strength

‘Ultimate strength’, ‘ultimate tensile strength’ and ‘tensile strength’ mean the same thing. The word ‘ultimate’ is useful because tensile strength determines the maximum stress that a material can withstand while being stretched or pulled before breaking. In brittle materials, the material breaks soon after the yield point has been reached.

Fracture Strength

‘Fracture’ or ‘breaking strength’ are also other terms for tensile strength. Given we’re talking about a stress value at which the test specimen separates into two distinct pieces, fracture or breaking strength are also useful terms to help explain the tensile test stage.

Key differences between yield and tensile strength

These are some of the major differences between yield strength and tensile strength:

- Yield strength is a measurement to determine the maximum stress that can be applied before permanent shape change is achieved in ductile materials. Whereas, tensile strength is the point of fracture.

- Deformation of materials occurs after yield strength has been reached then tensile strength is tested. In brittle materials, tensile strength is reached with minimal or no yield.

- In brittle materials, the material breaks soon after the yield point has been reached. In ductile materials, the yield strength is observed. Then ultimate strength is measured as the material continues to elongate to the breakpoint.

Yield and tensile strength are key performance indicators

From shelf brackets to bridges and satellite components, yield and tensile strength measurements determine how a structure or component will perform when subjected to various applied loads. How and when you apply these measurements, then analyse their results, will determine both the safety and effectiveness of your project. Sometimes it isn’t ultimate tensile vs yield strength; sometimes it’s ultimate tensile and yield strength.

Read about our projects where yield and tensile strength tests are an integral part of our sheet metal and fabrication processes.