Architectural

Metalwork Services

High-end architectural metalwork:

Aesthetically-pleasing metal structures and components designed, fabricated and installed.

Our architectural metalwork customers are in construction and related-industries. They’re architects, designers, re-fit specialists and their contractors working on both residential and commercial projects. Our work starts with understanding their end goal, and how we can best achieve it – from handrails and balustrades to canopies and decorative panels. Then comes the planning, sourcing and fabrication, followed by installation. Often, we make specialised parts, using raw materials such as steel (including stainless steel) and aluminium.

There are two sides to our business – fabrication and components – both of which come into play with architectural metalwork. Most importantly, our customers trust our fabrication capabilities to achieve structural integrity in compliance with H&S regulations and standards such as EN1090. Then, our work with precision components means we are skilled in the detailed nature of making something look really good.

What do we offer our architectural metal fabrication customers?

Our architectural metalwork customers rely on Alroys to deliver a full, trouble-free service from design through to installation. Integral to this service, are the following elements:

- Interpreting a brief – grasping exactly what the customer wants to achieve, and recommending the best way of achieving it

- Effective project planning – competitive pricing and efficiency throughout

- Solutions-led – making challenges and problems go away

- Safety-conscious – compliance with regulations and standards, such as EN1090

- Sourcing and handling multiple materials – eg glass and wood in addition to metal

- Being trustworthy – taking responsibility for the whole project, including managing other contractors, such as glaziers or air con engineers.

- Managing installation challenges –working round other trades; exercising extreme care at the second fix stage (when all the visible fittings and products will be installed, such as flooring and tiling)

- Communication – regular and reliable liaison and updating

Call For a Quote:

01438 355687

What kind of architectural metalwork do we fabricate?

The list of jobs for architectural metalwork is long and fascinating: balconies, handrails, staircases, balustrades, canopies, interior artworks, protective panels. Most have a function beyond looking impressive: stop people falling, aid them walking up stairs, protect them from the elements, etc.

Our projects often involve multiple design stages and frequent site-visits to check measurements and installation challenges. Once customers appreciate the real value we can offer – understanding the extent of what we can do and how we work – they entrust us with other more complex projects.

For one of our construction customers, we fabricated a brise soleil to shade foot passengers from the sun on a new bridge link between two buildings. Our brief was to match an existing brise soleil, used on the two buildings either side of the bridge. As the buildings were built 30 years ago, and no accurate drawings could be found, we visually matched our new bridge version with the existing ones.

Our customers rely on us to take on a project and manage it through to completion, solving problems as we go. Busy professionals in their own field, they sometimes need detailed explanations regarding the metalwork and how we intend to progress. It could be that creating a prototype is the most effective way forward. As we did for a customer wanting some elegant metal bases for their tables. Making sure the tables were stable was the challenge and the prototype stage for this project tackled the issue head on.

Aluminium doors for lab cupboards

Manufacture and install 24 doors perforated to a minimalist design. The challenge was making sure the doors were uniform in size and appearance so they fitted perfectly into uneven cupboard cavities. We spot-welded the aluminium as it’s neater, cleaner and less prone to distortion. As aluminium conducts heat and electricity, we had to work fast to avoid overheating the doors.

Project time: 4-6 weeks in total.

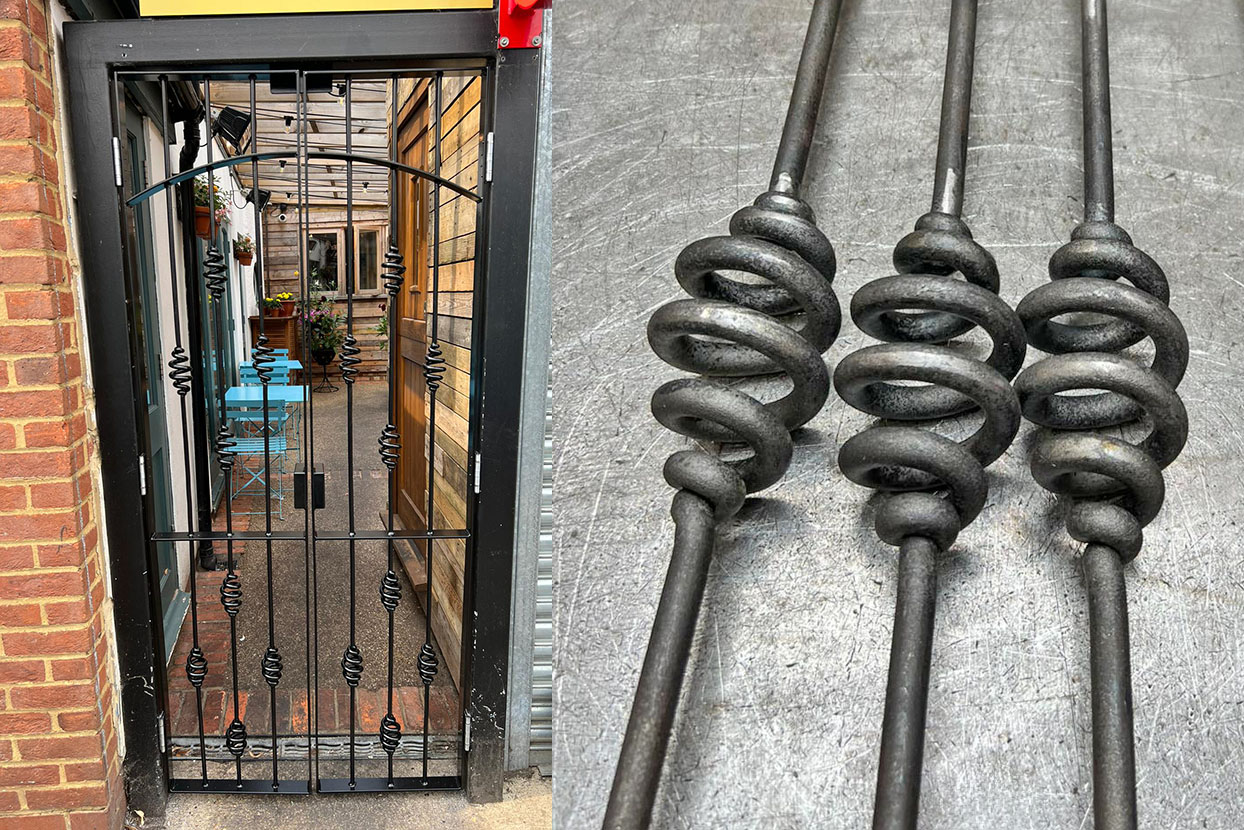

Ornamental gate for local restaurant

Design and manufacture a secure but elegant gate for the entrance to a Spanish restaurant’s outdoor eating area. Using mild steel, we produced a sturdy, lockable gate featuring an ornamental design. Then we powdered coated the gate in black and fitted it before the restaurant opened.

Completion time: 3-4 days from design to installation.

Glass balustrade staircases

Two sleek, minimalist staircases for a new office development, comprising glass and powder-coated aluminium. Together with the customer and their structural engineer, we designed and solved structural issues. We also sourced all the materials, manufactured, assembled and installed the staircases over a 6 week period.

Protective entrance canopies

Contemporary steel and aluminium protective canopies, complete with signage and lighting. Working with the customer’s designers and structural engineer, our specialist team planned and created architectural canopies for two entrances: light enough for the brickwork to support but able to withstand the weight of rain and snow.

Project time: 8 weeks in total.

Cosmetic, backlit panelling

Stunning, high-spec architectural metalwork for a new ultra-modern house: cosmetic wall panelling plus golden LED lighting, decorative window infills, stair case and handrail. The material used was aluminium together with special adhesives to ensure all fixings were hidden and the desired ‘wow’ factor was achieved.

Project time: 10 weeks.

If you’ve got an architectural metalwork project, get in touch, tell us what you’re planning and let’s see how we can achieve it.

Alroys Sheet Metal Services

Prototyping

Take control of the unknown by testing first with a prototype. We give you the ability to fully test a design concept, iron out unwanted flaws at the earliest stage and create a working model, approved by your project team.

CNC Punching

By utilising the combination of 3D modelling, CAD/CAM software and Trumpf technology, Alroys is able to offer a complete solution to all your requirements, no matter how unique.

CNC Bending (or Forming)

With advances in technology, CNC (computer numerically controlled) bending technology now gives you the ability to produce almost any component design, saving time and money along the way.

Sheet Metal Welding

This manufacturing process fuses metals together using extremely high temperatures. During cooling, the joints harden, creating permanent structures.

Sheet Metal Assembly

Prior to installation, the assembly stage is the realisation of your project. We take each component part and, in our manufacturing facility, we assemble them, testing each for fit and quality.

Contact Us

Free Consultation

Talk to us about your next project

With over 60 years experience, we have built up a reputation of providing high quality products, on time delivery and professionalism.

As a leading steel manufacturer in the UK, we can handle any project using materials such as stainless steel or aluminium. Whether you come to us with a blank canvas or ideas already in mind, we will take on any request and contend to calculate and guarantee exceptional results.

Call us to discuss your next project.

+44 01438 355687

Arrange an appointment

If you'd like to visit us to discuss your next project in person, please use the number above to arrange a time suitable for you.

Download our brochure

Click here to download our brochure.

Depending on your browser settings, the brochure will either open in a new browser window (save to your computer to view) or will download directly to your computer. You will require a pdf reader to view our brochure once saved to your computer.